The Advantages of ASRS warehouse

Storyboard Text

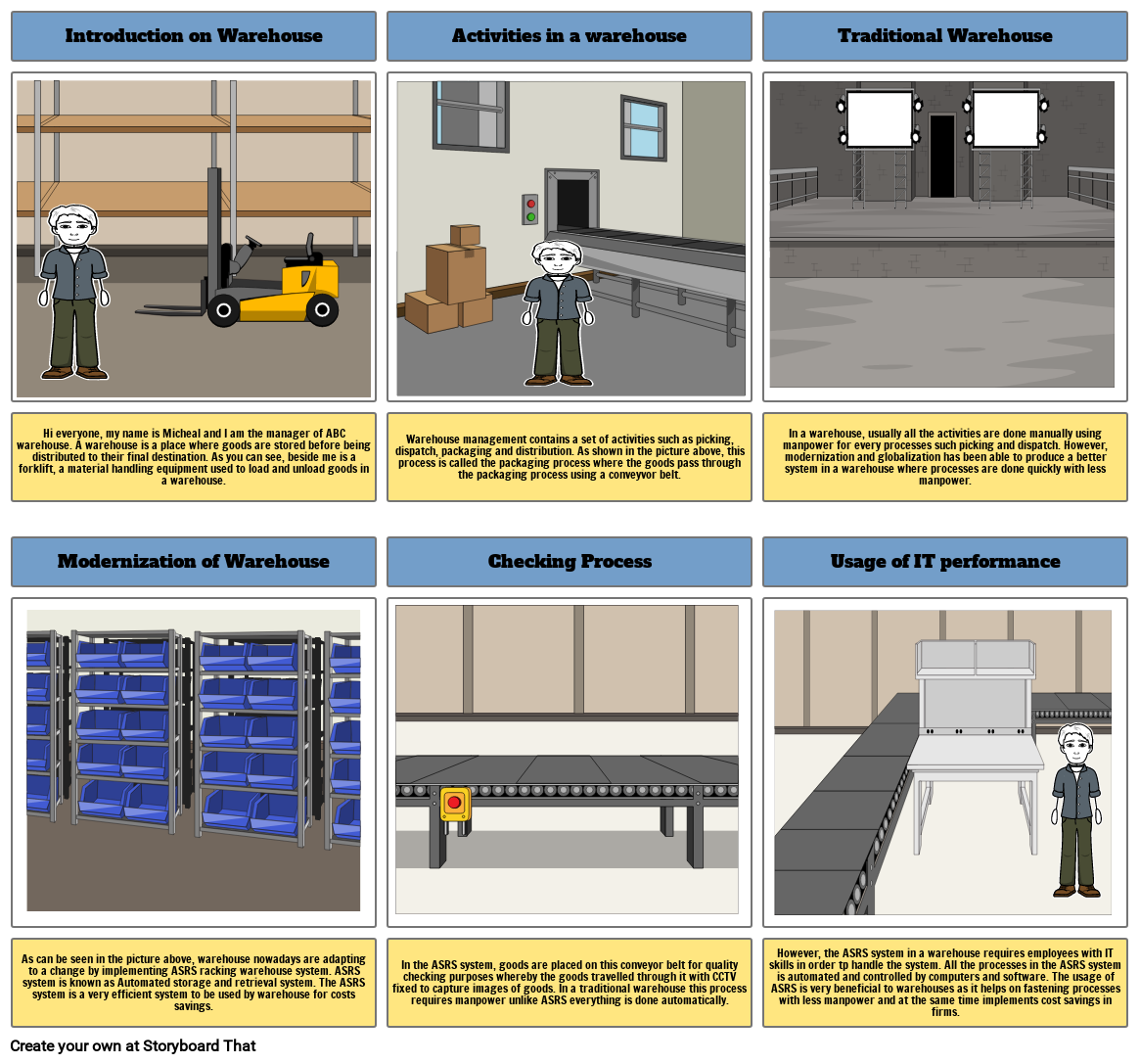

- Introduction on Warehouse

- Activities in a warehouse

- Traditional Warehouse

- Hi everyone, my name is Micheal and I am the manager of ABC warehouse. A warehouse is a place where goods are stored before being distributed to their final destination. As you can see, beside me is a forklift, a material handling equipment used to load and unload goods in a warehouse.

- Modernization of Warehouse

- Warehouse management contains a set of activities such as picking, dispatch, packaging and distribution. As shown in the picture above, this process is called the packaging process where the goods pass through the packaging process using a conveyvor belt.

- Checking Process

- In a warehouse, usually all the activities are done manually using manpower for every processes such picking and dispatch. However, modernization and globalization has been able to produce a better system in a warehouse where processes are done quickly with less manpower.

- Usage of IT performance

- As can be seen in the picture above, warehouse nowadays are adapting to a change by implementing ASRS racking warehouse system. ASRS system is known as Automated storage and retrieval system. The ASRS system is a very efficient system to be used by warehouse for costs savings.

- In the ASRS system, goods are placed on this conveyor belt for quality checking purposes whereby the goods travelled through it with CCTV fixed to capture images of goods. In a traditional warehouse this process requires manpower unlike ASRS everything is done automatically.

- However, the ASRS system in a warehouse requires employees with IT skills in order tp handle the system. All the processes in the ASRS system is automated and controlled by computers and software. The usage of ASRS is very beneficial to warehouses as it helps on fastening processes with less manpower and at the same time implements cost savings in firms.

Over 30 Million Storyboards Created

No Downloads, No Credit Card, and No Login Needed to Try!